Last edit: 03/06/2024

EN ISO 13577 is the series of standards, at international level, that give prescriptions on how to design a safe Industrial Furnace.

In Europe, so far, we followed EN 746 series, whose principles are derived from the ISO standard. Latest Edition of EN 746-2 is dated 2010. Latest edition of EN ISO 13577-4 is dated 2014, A new edition was published in July 2022. GT Engineering has participated in its development, giving a significant contribution to the Functional Safety Part. A new edition of EN ISO 13577-2 was published in 2023. By June 2024 all national editions of EN 746-2 have been withdrawn (Italy, UK, France, Spain etc..) and that means EN ISO 13577-2 and EN ISO 13577-4 are the only reference for a the safe design of an Industrial Furnace.

EN ISO 13577 consists of the following parts, under the general title Industrial furnaces and associated processing equipment — Safety:

Part 1: General requirements

Part 2: Combustion and fuel handling systems

Part 3: Generation and use of protective and reactive atmosphere gases

Part 4: Protective systems

The acronym used in the standard to indicate industrial furnaces and associated processing equipment was IThE (EN 746-2) and it is now TPE.

What are the main changes compared to the 2014 edition of EN ISO 13577-2?

In General, the two new standards have nearly twice the number of pages than the EN 746-2 (220 vs 130 pages) and that is an evident sign that they better clarify how to design a safe furnace.

The group who develops the standard decided to remove the prescriptions for Solid Fuels. A dedicated standard may see the light in the future.

In the new standard it is not clear what procedure the furnace manufacturer has to follow to test the gas train during commissioning.

Gas pressure Boosters have been added to the standard with several prescriptions

[ISO 13577-2: 2023] 4.4 Gas pressure boosters

When a gas pressure booster is used to ensure stable operation and control of the heating system, the

following shall apply. The selection of seals and devices for the booster system shall consider:

— temperature increase by isochore compression of the gas and

— engine waste heat spreading from the booster into the pipework especially in case the gas flow

stops (non-consumption of the TPE).

Line burners are now defined and their safety is now clearly stated.

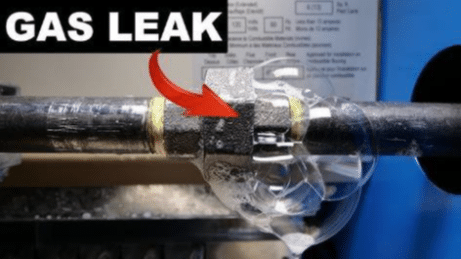

How to deal with the risk of the presence of an explosive atmosphere around the Gas train and outside the furnace is now well specified.