Last edit: 11/08/2023

The Mean Time To Failure (MTTF) is a statistical parameter related to the reliability of the components used in the safety system.

It represents the average life of a component before it is damaged. With MTTFD, only the portion of dangerous failures is considered.

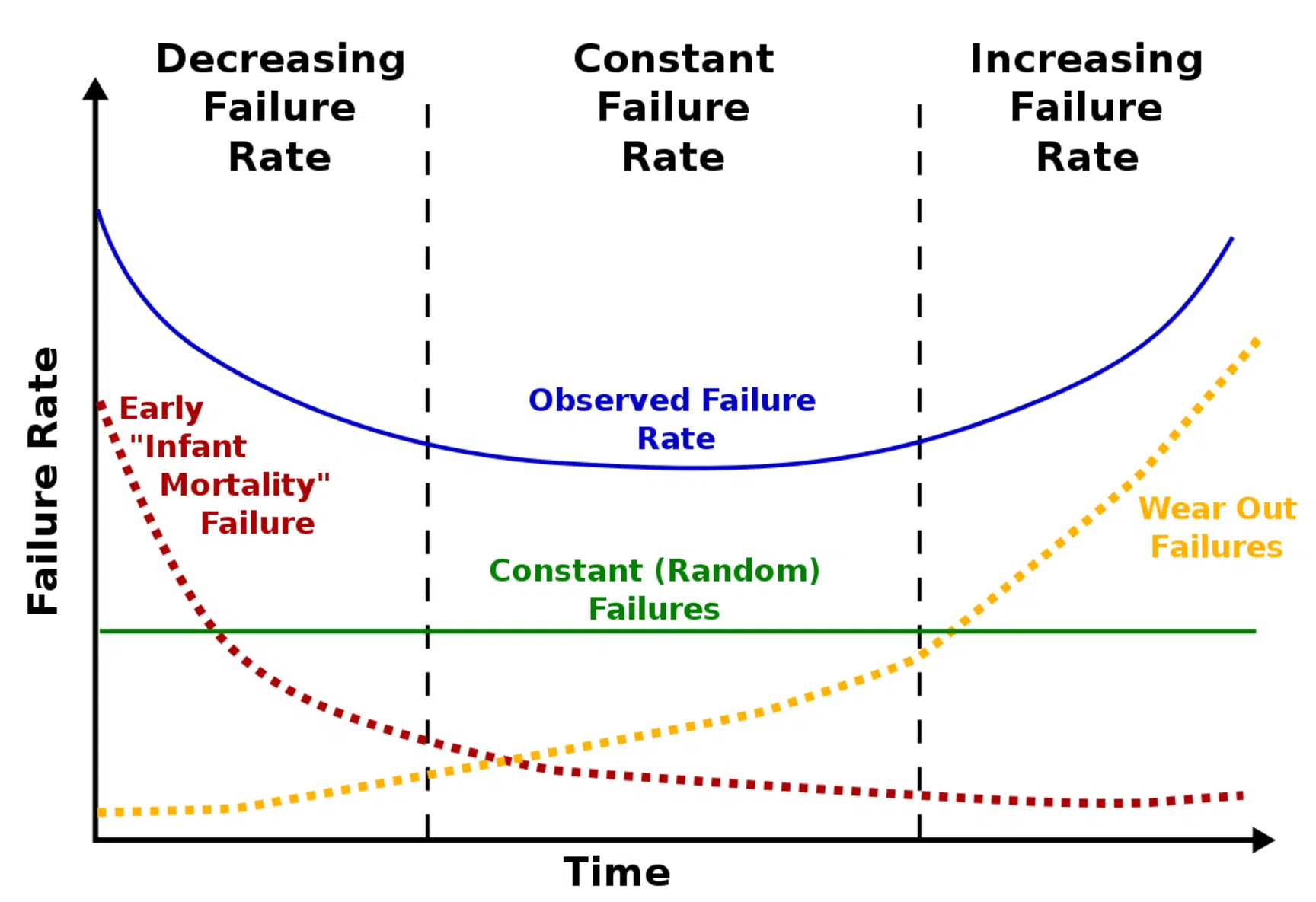

The MTTFD is associated with the failure rate λD referring only to dangerous faults. The failure rate has a variable trend over time, in particular, it is:

- High and gradually decreasing at the beginning of the life of the component;

- Constant until the estimated “Useful life“;

- Increasing after exceeding the estimated “Life time“.

The trend of λ as a function of time is shown below. The curve is called “Bathtub Curve“.

To associate MTTFD with λD, EN 13849-1 makes the following simplifying assumptions:

- The component is considered to have already passed the first life stage;

- The component supplier defines a “Mission time,” which is equivalent to the period during which the failure rate can be assumed to be constant. This is the key assumption underlying all functional safety standards, whether High Demand (ISO 13849-1 or IEC 62061) or Low Demand (IEC 61511), and represents the component’s useful life time.

With these assumptions, it can be shown that MTTFD=1/λD

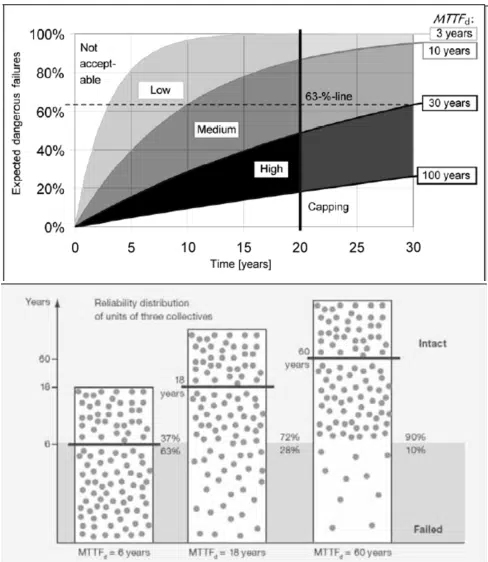

As mentioned above, the MTTF and MTTFD are statistical parameters, so they are neither a guarantee that the component will work before the time limit is exceeded, nor that, once this threshold is exceeded, the component will definitely fail.

It is shown that, for example, in a batch of components with a MTTFD= 6 years, after 6 years , 63% of the components in the batch had a dangerous failure. In contrast, in a batch of components with a MTTFD= 60 years, past 6 years, only 10% of them have a dangerous failure.

In the side graphs, the statistical percentage of failed components as time increases for 4 different MTTFD values is shown.

International Standards dealing with MTTFd or B10d for components

Generally, when considering wear components, an additional statistical parameter called B10 is defined. B10 indicates the number of cycles beyond which 10 percent of the components under consideration by the manufacturer will fail. With B10D,on the other hand, only hazardous failures are considered.

To calculate MTTFD from B10D, the following relationship can be used:

MTTFD= B10D/0.1*nop

Where nop represents the number of operations the component performs in a year

The B10 and B10D are generally provided by the manufacturer of the safety component. If such data are not available instead, the values provided by ISO 13849-1 can be used. Below is an excerpt from Table C.1 of the Standard in which some components are listed with relative MTTFD or B10D.