Last edit: 07/08/2023

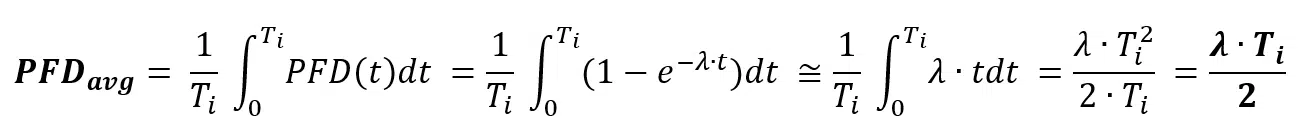

The Average PFD is defined as

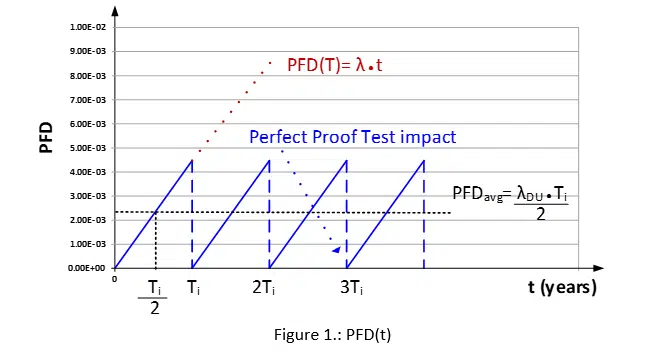

Ti is the time when the system is function tested. The PFD(T) of a SIF, that is periodically tested, is represented by a saw tooth curve, with a probability ranging from low, just after a test, to a maximum, just before the next test.

Its average value, or PFDavg, is represented in Figure 1 .

Dangerous Failures

When dealing with Safety Critical Systems, the important failures are the dangerous ones. Those can be divided into Dangerous Detectable by the Diagnostic tests and Dangerous Undetectable.

Dangerous Undetected Failures (DU) prevent the activation, on demand, of the safety system and are also called dormant failures.

Dangerous Detected Failures (DD) are may be found immediately when they occur, for example, by an automatic built in self-test. A short circuit on a normally closed free voltage contact can be revealed with the so called “trigger” function, now available in almost all Safety-related Control Systems (chapter 3).

In low demand mode, Dangerous Detected failures do not play a role in the Unreliability of a Safety System, since, often, they are detected as soon as they appear and the process is immediately shut down. Therefore, the only significant failures that influence the value of the PFDavg, are the DU failures. Therefore, Equation can be written as:

The test interval Ti is decided based upon the demand rate, so that there is a fair chance that a Dangerous Undetected fault is revealed and corrected before a demand occurs, such that a hazardous event is avoided.