Last edit: 22/10/2024

Subsystems of Category B must use Basic Safety Principles, where applicable and detailed in ISO 13849-2, and shall be designed according to relevant standards. That should guarantee that they can withstand expected operating stresses and influences of the processed material, like detergents (thanks for example, to the use of stainless steel) or other relevant external influences, like mechanical vibrations.

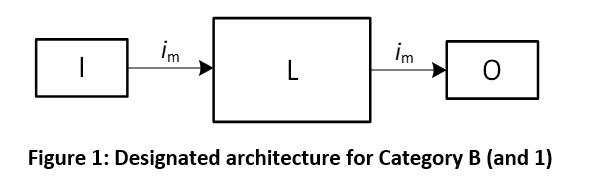

The Reliability block diagram of a Category B (and 1) is shown in Figure 1. It is shown as having an Input a Logic and an Output however, each category is applicable to a subsystem: either an Input subsystem or an output subsystem, for example. Therefore, do not be confused by the figure: it shows a subsystem and not necessarily a Safety-related control system.

Keys:

- Im represents the interconnecting means, typically electrical wires

- I represents the Input

- L represents the Safety Logic; it can be also a wire or a Safety Module (non-programmable) or a Programmable Logic.

- O represents the output; it can be a contactor or a solenoid valve

With this category, there is no need of diagnostic coverage and CCF considerations are not relevant; the maximum PL achievable is PL b.

Being a single channel, a single fault can lead to the loss of the safety sub-function.