Last edit: 18/11/2024

There is often confusion as to whether or not type B residual current devices (RCDs) are required to protect lines in which variable speed drives are used to control asynchronous motors: let’s clear up any doubts!

The Doubt

Is a type B Residual Current Device compulsory when using Variable Speed Drives or Power Drive Systems (PDS)?

Considerations

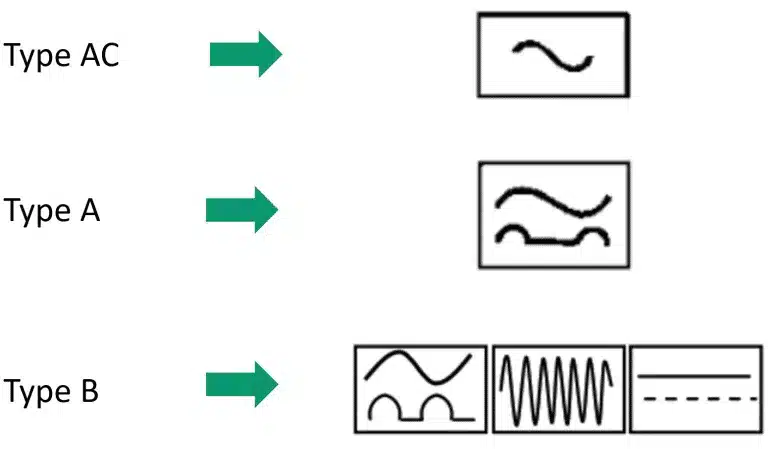

Residual Current Devices are of different types:

- Type AC RCDs: they detect residual sinusoidal alternating currents. Type AC RCDs are suitable for general use and cover most of the applications in practice.

- Type A RCDs: in addition to the detection characteristics of type AC, they can detect pulsating DC residual current.

- Type B RCDs: in addition to the detection characteristics of type A, they can detect a pure DC residual current, that may come from a fault inside a Variable Speed Drive.

Power Drive Systems have a product standard: EN 61800-5-1: Adjustable speed electrical power drive systems – Part 5-1: Safety requirements – Electrical, thermal and energy.

Hereafter what the standard specifies regarding the compulsory use of a Type B Residual Current Device.

[EN 61800-5-1: 2009] 6.3.6.7 Protective earthing conductor current

[…] When 4.3.10 b) applies, a caution notice and the symbol ISO 7000-0434 (2004-01) (see Annex H) shall be provided in the user manual, and the symbol shall be placed on the product. The caution notice shall be: “This product can cause a d.c. current in the protective earthing conductor. Where a residual current-operated protective (RCD) or monitoring (RCM) device is used for protection in case of direct or indirect contact, only an RCD or RCM of Type B is allowed on the supply side of this product..”

The important word in the above language is “Where”. The standard is telling us that if, in order to protect a machine or part of it from indirect contacts, the manufacturer must rely upon a RCD, it has to be a type B.

When do we need to rely upon RDC for indirect contacts?

1. In TN systems where the Circuit Breaker or Motor Controller is not able to open the fault loop within the time specified by the IEC 60204-1 standard (0,4 s or 5 s).

2. In most of TT systems (in Italy in all TT systems).

Conclusion

If your machine is installed in a TN system and you have verified that, in case of a fault, a magnetic protection (Branch Circuit Protection in USA Terminology) opens the fault loop, you do not need to install any RCD and in particular a Type B RCD is not required.