Last edit: 10/07/2023

The assessment and risk reduction process is detailed in various standards.

An important aspect of the risk reduction methods suggested by the standards concerns the reduction of energy levels.

When possible, access to a segregated area should be carried out at zero energy with the elimination and isolation of hazardous energy (preferred method to reduce the risk). However, some activities require partial or total energization to be performed and to operate machine elements with disabled protection devices. For these specific activities, reduced energy operating modes are are a way to reduce the risk for the operator or the maintenance person.

Some types of machines are subject to specific standards that define the operating modes in terms of reduced energy values and other additional conditions.

However, many others, are not covered by a specific standard and therefore manufacturers may not know what threshold to use.

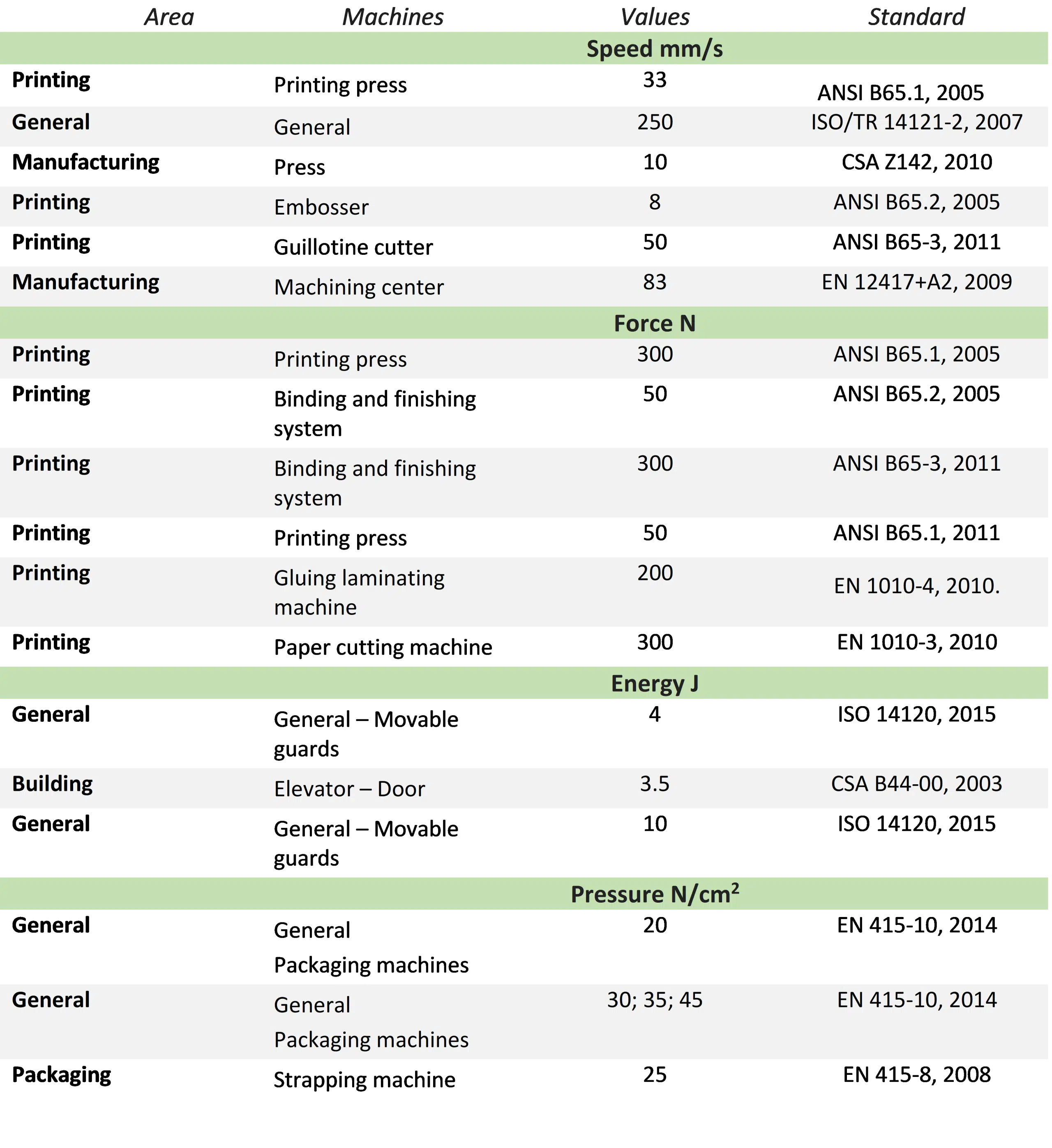

Here we present some values stated in technical standards, grouped in the following way:

– Speed (mm / s): to be used in case of objects that move at constant speed (Robot arm).

– Force (N): in case of constant pressure without acceleration of the element.

– Kinetic Energy (J): to be used in case of objects that move at increased speed (a gate/protection falling from a certain hight).

– Pressure (N / cm2). In case certain part of the body is subject to the possible damage.

Just as an example, here what exactly the standardo ISO 14120 states in 5.2.5.4:

Where guards are power operated, they shall not be capable of causing injury (for example, from contac pressure, force, speed, sharp edges).

Where a guard is fitted with a protective device which automatically initiates re-opening ofthe guard, the closing force shall not exceed 150 N and the kinetic energy of the guard shall not exceed 10 J. Where no such protective device is fitted, these values shall be reduced to 75 N and 4 J respectively.

These values are only applicable when a wide closing edge is used and no hazards from cutting or shearing are present.

In general, values differ because the type of moving element depends upon the type of machine.

The message is that there is no such thing as one threshold of reduced energy. It is necessary to determine what risks the operators are exposed to and how the injuries can occur and a risk analysis has always to be done in order to justify the values used.