Last edit: 31/05/2024

The Gas Train is a part of a combustion system, featuring the components that carry the fuel from the network (or from the tank) to the burner. A gas train can feed one or more burners. The designer must consider the Standard EN ISO 13577-2. This Standard states the requisites that guarantee the safety of people and equipment and the correct functioning of the system. It also indicates which safety devices should be used.

Manual isolating valve and filter

The manual isolating valve is placed at the beginning of the gas train, to allow the user to disconnect the system. The filter has to avoid that particles (from the pipework or the gas) can flow through the train, damaging the system.

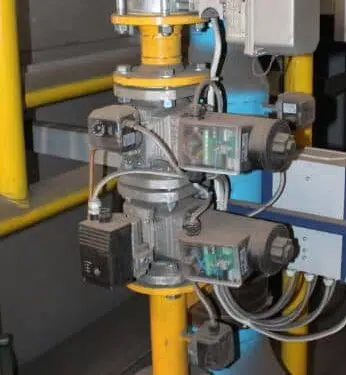

Automatic shut-off valve with valve proving system

The shut-off valve could be placed upstream or downstream of the gas regulator. It is normally open and, if a problem related to the safety of the combustion system is detected, it closes, interrupting the gas flow. When the power of the burner exceeds 1200 kW, a valve proving system must be provided.

Gas pressure governor with cut-off valve

The gas pressure regulator has to provide the pressure difference between the distribution system and the burners. An over pressure cut-off valve is normally applied upstream of the gas pressure regulator, interrupting the gas flow if the downstream pressure exceeds a threshold value. It can be included in the gas pressure regulator too.

Pressure switches

Usually there are two pressure switches. One detects if the pressure goes below a predetermined value (low gas pressure protection) while the other detects if the pressure exceeds another value (high gas pressure protection).

Relief valve

Unlike the shut-off valve, a relief valve is normally closed. When the pressure exceeds a threshold, the valve opens. It prevents a breakdown of the gas regulator.