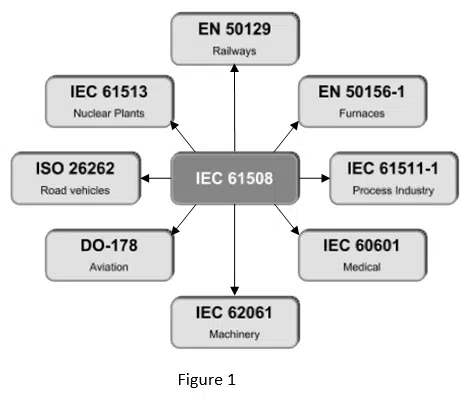

IEC 61508 (all parts)

This is the “mother” of all Functional safety standards used in several industries worldwide. It was written in order to allow the use of Electronic components in safety critical systems.

Functional Safety

Example of PFDAvg Calculation

We want to calculate the PFDavg for a low demand mode Safety Loop involving a pressure transmitter, an analogue barrier, two electronic safety modules and the STO (Safe Torque off) of a Variable Speed Drive.

Process Safety

The Modular Approach for Distribution Panels

The doubt: in order to CE mark my distribution panel, shall I do EMC tests?

Machinery Safety

Is IEC 61439-1 applicable to Industrial Control Panels?

The doubt: in order to CE mark an Industrial Control Panel, shall I follow the prescriptions given by IEC 61439-1?

Electrical Safety and Arc Flash Mitigation

Double Bonding

THE DOUBT

We sometimes notice electric motors having a double bonding. Is it mandatory?

Electrical Safety and Arc Flash Mitigation

The Seven Golden Rules for a successful Risk assessment and Risk Reduction

There are about 700 harmonised standards to the machinery directive. Few of them, like ISO 12100, are about the risk assessment; the majority are about how to reduce the risk.

Machinery Safety

Six key symbols for Electrical Safety

Electrical Safety is well standardized, in the sense that there are may technical documents written on the Subject, normally by the International Electrotechnical Commission, or IEC.

Electrical Safety and Arc Flash Mitigation

Contactors used in Safety Applications

There are three types of contactors used in Safety-related control Systems:

Electrical Safety and Arc Flash Mitigation

ISO 13849-1

It is one of the two standards used in machinery and, at least in Europe, it is the most used of the two, the other being IEC 62061. It is divided in two parts:

Functional Safety

Direct Opening Action

The electrical output of an interlocking device has two types of technologies

Machinery Safety

IEC 62061

This is the second standard applicable to machinery and, so far, the least used for the reasons explained in the book. However, there is confidence that, with the publication of the 2021 edition, there will be more and more machinery manufacturers wh...

Functional Safety

"Proven in use" and "Prior use"

THE DOUBT: What is the difference between a Proven in Use and a Prior Use Device?

Actually the two terms are quite similar and it is very easy to mix t...

Process Safety